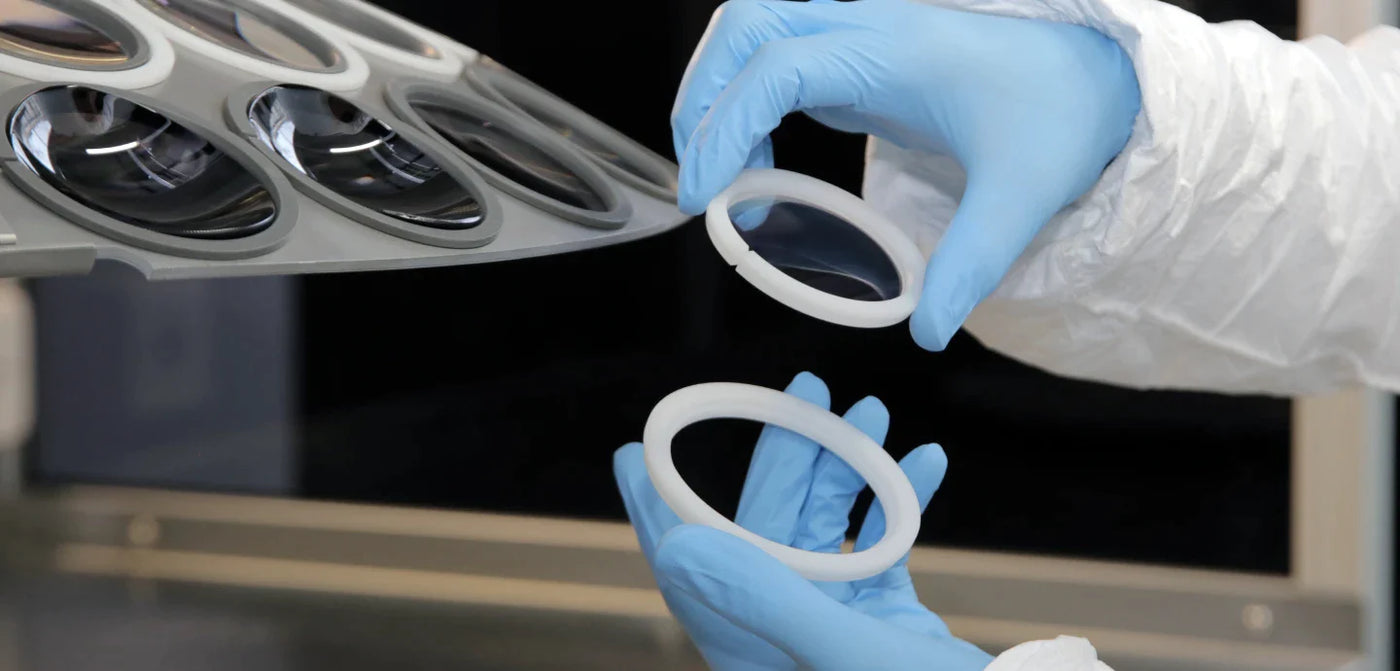

High Precision 2-Step System Redundancy

We perform a double measurement process to eliminate error, distortion and ensure perfect fitment.

Step 1 : We create a 3D rendering of the exact dimensions of the frame using a patented double-sided high base curve tracer with an enhanced soft-touch multi-pivot head.

Step 2 : To avoid errors that may occur with the optical tracer, the profile of every lens is captured using an extremely powerful optical scanner. This meticulous process eliminates the effect of perspectives and distortions by enlarging each lens profile.

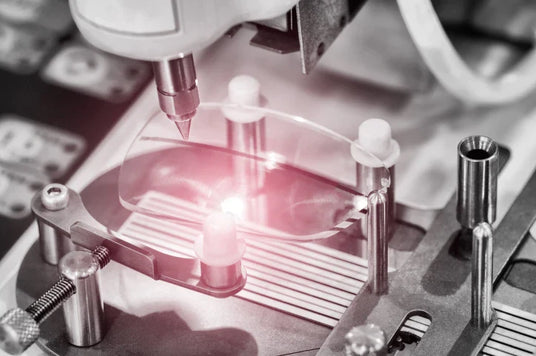

A Cut Above the Rest

By only using advanced Dry-Cut Diamond Milling technology Seek Optics guarantees:

- No headaches or eyestrain

- No optical distortion

- No shifting of the optical center

- No twisting of the optical axis

- No damage to lens coatings or surfaces

- No water waste

- No water contamination

Each set of lenses is manufactured in-house at our Pennsylvania Headquarters and custom-made for you.

5-Step Quality Control

Before and after the edging process, every set of Seek lenses goes through several inspection processes by our signature 5QC verification system:

- Optical Center Verification

- Lens Axis Verification

- Size and Circumference Verification

- Lens Power Verification (Rx lenses only)

- Frame Fitment Verification

The integrated quality control system guarantees the precise measurement of all the optical parameters by analyzing 100% of the production process. Each lens shape we offer is tried and tested to ensure a tight and secure fit.

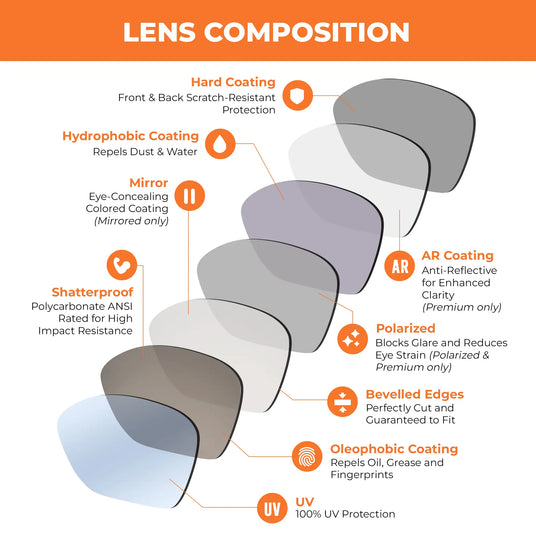

Your eyes need protection

When you buy new replacement lenses for your sunglasses from Seek Optics, you can be certain that these replacement lenses will be made from the most innovative sunglass lens materials currently on the market. Here are some of the features that make Seek Optics Replacement Lenses special:

Seek Optics vs. the Competition

Many of our competitors sell cheap, thin plastic sunglass lenses with inexpensive lens coatings that are unsuitable for work or sports and will not last. Due to inadequate UV protection, low impact resistance, and optical distortion, these low-quality materials will cause long-term harm to your eyes.These lenses are poorly made to save money, resulting in annoying rattling or a loose fit. This happens because these competitors are not opticians; they are simply product resellers with no knowledge or expertise to pass on to their customers. They manufacture these sunglass replacement lenses in massive batches without quality control.

Seek Optics is an American optical lab with three generations of expertise in the eyecare sector. We only use the highest quality optical polycarbonate for our custom replacement lenses to ensure your eyes are protected from shattering and distortion. Every set of our custom replacement lenses is personally handled and cut by our opticians just for you. After production, your lenses are tested with our signature 5-Step Quality Control. We promise that our sunglass replacement lenses will have the proper thickness and base-curve for your sunglasses, so you won't have to worry about your lenses rattling or falling out!

Be Unique!

Let your sunglasses be an expression of your personality! Our creative engraving package gives you the freedom to totally customize your lenses with words, logos, drawings, initials, or icons!